Welcome to an inside look at one of my recent ventures – transforming a basic diagram into a 3D printed pool lift. This project, though not necessarily practical in its function, serves as an excellent educational tool and a testament to the power of digital fabrication.

The Initial Spark

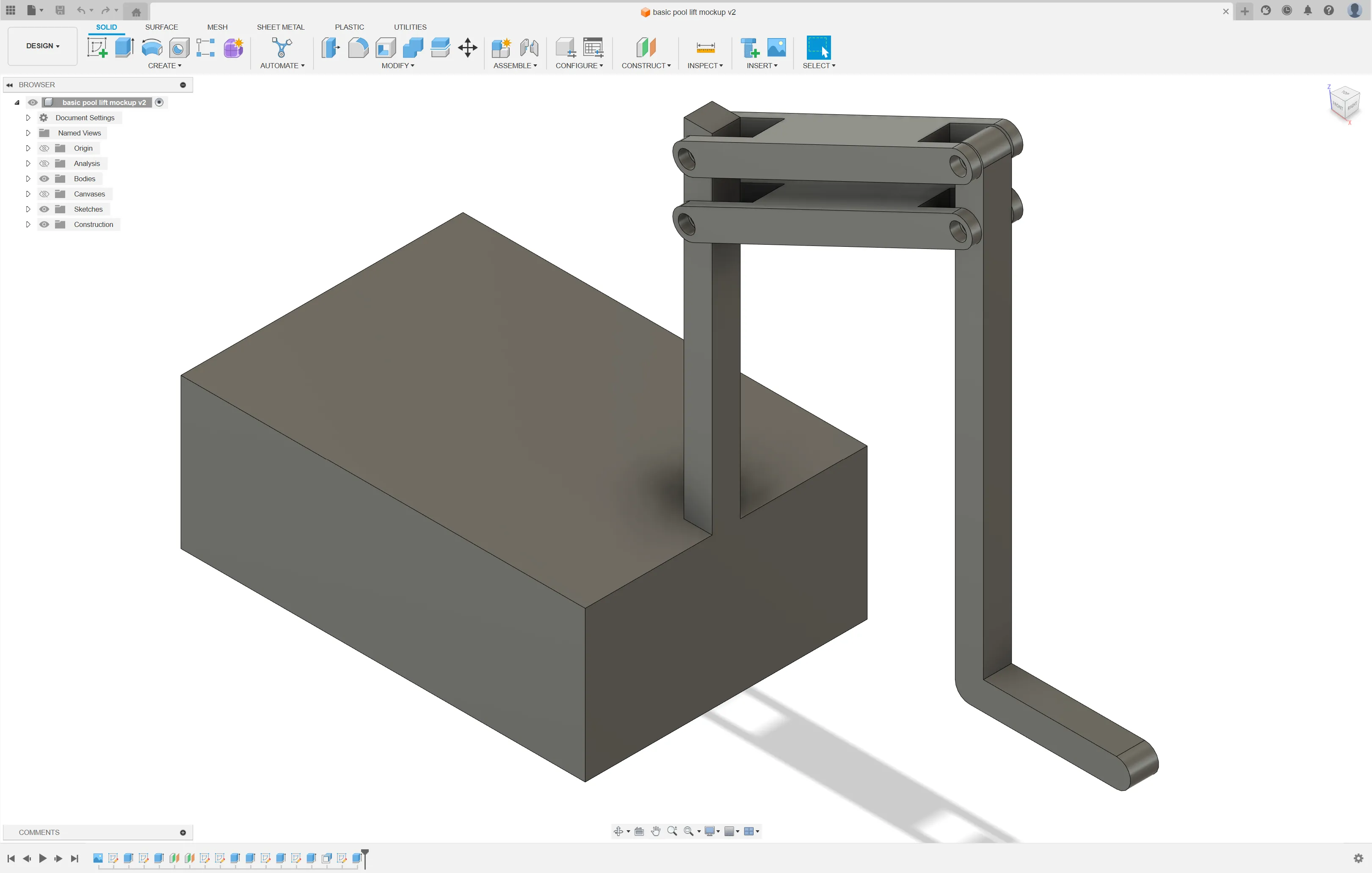

It all started with a basic diagram in a college statics class. While the drawing was intended merely for theoretical discussion, I saw an opportunity to bring it to life. Using Fusion 360, I created a mockup of the pool lift, complete with a seat, hydraulic cylinder, and a four-bar linkage – the essential components of a real pool lift. This process wasn’t required or prompted; it was driven purely by my passion for making ideas tangible.

First Prototype

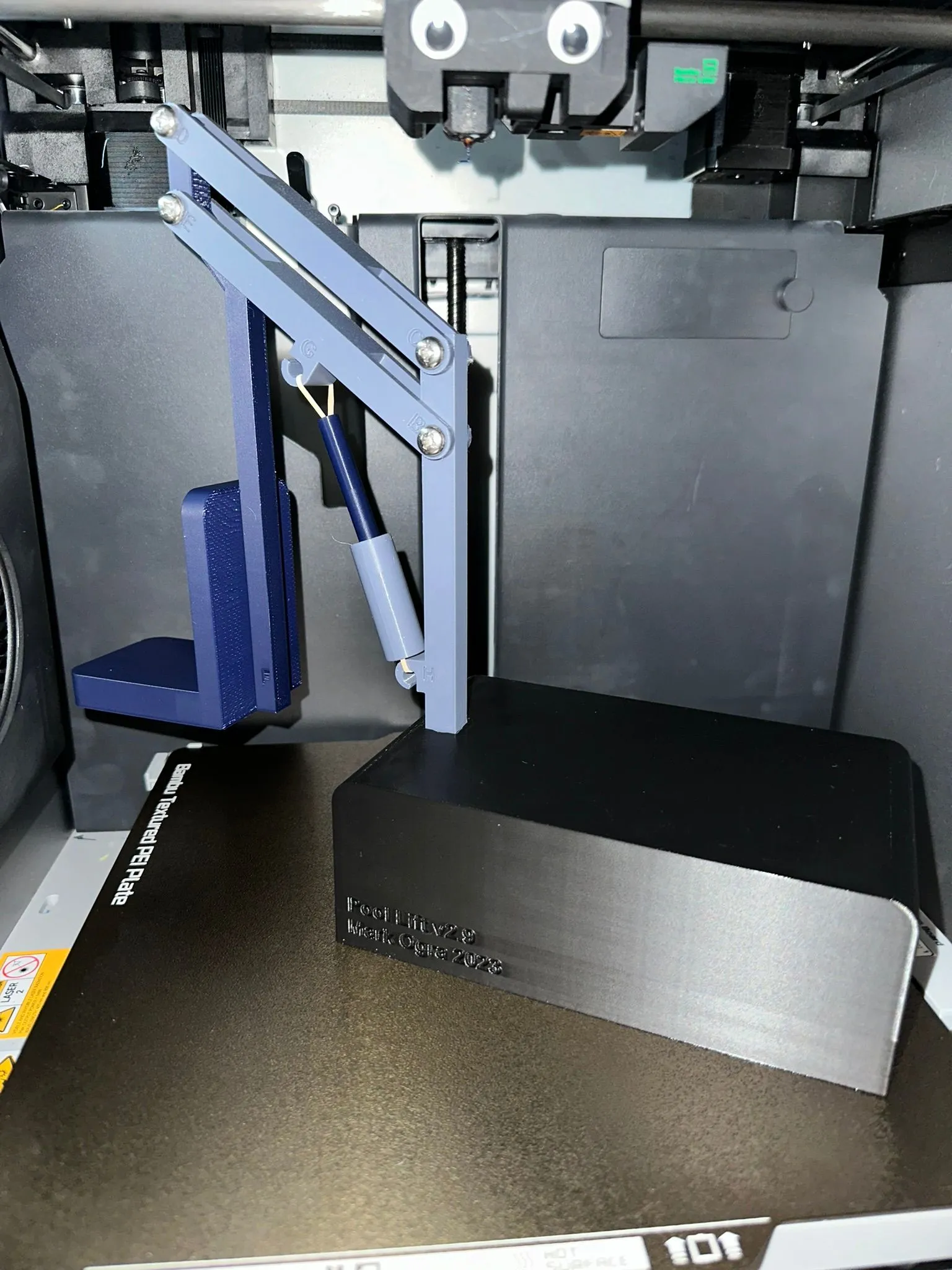

The prototype, created on my Bambu Lab X1-Carbon, featured a novel approach to the hydraulic cylinder, using a rubber band. This initial model not only demonstrated the pool lift’s mechanics but also highlighted the creative potential of 3D printing.

Collaboration and Progress

The project caught the eye of my professor, who suggested expanding its scope. This led to a small batch production of 20 pool lifts, commissioned by the Department of Engineering Education through the research foundation. Our email exchanges, a blend of technical discussion and administrative coordination, guided this process.

Technical Insights:

- Filament Usage: Bambu Studio indicated that for 20 models, we would need approximately 3.72 kg of filament, spread across black, grey, and blue colors. The final design required 3 spools of black, 1 spool each of grey and blue filament.

- Hardware Upgrade: The design evolved to use larger M5 hardware for enhanced stability and durability.

Administrative Dynamics

Navigating through the administrative maze was an educational experience in itself. The project required detailed logs of my working hours and meticulous coordination with the department for resources and approvals.

Final Design – A Teaching Tool

The final design, while not functional in a traditional sense, serves as an interactive model for educational purposes. It provides a tangible way to understand the mechanics of a pool lift, something that mere diagrams or lectures cannot fully convey.

Digital Manufacturing Lab Option

While the Digital Manufacturing Lab in Bonner Hall was available and free for student projects like this, I chose to use my own printer. This decision was based on efficiency, cost, and the personal satisfaction of using my own equipment.

Sharing the Design

For those interested, the 3D printable model files are available on Printables.com. I encourage fellow enthusiasts and students to explore and perhaps even improve upon my design.

Conclusion

This project is a vivid example of how a simple class assignment can evolve into a meaningful educational tool. It showcases the intersection of technical skills, creativity, and the practical application of engineering principles.